REPAIRS

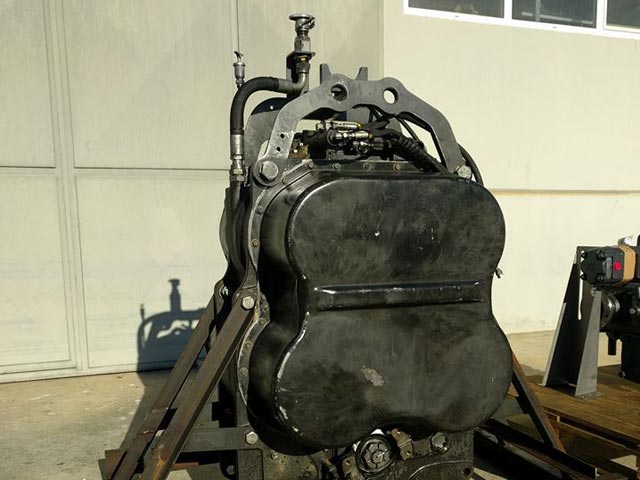

Our company is rebuilding hydraulic transmissions and axles for construction equipment for over 40 years now. The brands we specialize in are CLARK, DANA, ALLISON, VOLVO and ZF. By constantly investing in the education of our technical personnel and under the personal engagement of the owner of the company, Mechanical Engineer Mr. Christos Mourafetis, we verify that the quality of our services is always in agreement with the manufacturer’s specifications.

By using our complete technical library for all these brands, even the dismantling is being done according to the manufacturer’s specifications, and by using the correct tools. All subassemblies are cleaned and inspected so that we can estimate the damage, and most important, find the cause of the failure. We estimate the cost of the repair, and in conciliation with the customer, we decide if we will only repair the damage, or if we will make a complete overhaul of the transmission.

By cooperating with the best companies worldwide, we can offer the option to have all “one piece” converters to be rebuilt. We also stock our most commonly used torque converters so that we can offer service exchange units and save time and money to our clients.

Our close to zero failure rate is the proof that we are always doing our best when we repair your hydraulic transmission.

Finally, each hydraulic transmission or axle that is coming in our workshop is uniquely identified and an electronic file is kept for each repair, so that we can always go back to the data of the last repair, even if it was made many years ago.

Test Bench

Our company operates one of the very few automatic transmission test facilities in Greece, capable of testing from the small Allison AT545 (235 hp) used in buses up to the massive Allison H8610AR (1,100 hp) used in 100-ton dumpers. During testing the transmission reaches operating temperature; we check hydraulic circuit pressures in all gears, speed sensors, oil level and temperature sensors, and the correct operation of proportional valves where applicable. Gear shifts are performed via our in-house electronic platform to verify correctness and the demanded power in every case. All measurement data are logged per unit for future reference.

This way we are always certain the transmission operates correctly before installation on your machine, and that there will be no leaks or mechanical/hydraulic issues that would otherwise require removal again.

Repairs

Services

Our full transmission rebuild process includes:

External wash before disassembly.

Complete teardown of the transmission and subsystems (pump, pistons, shifter, etc.).

Thorough cleaning of all parts and wear assessment using dedicated measurements versus OEM specs.

Replacement of all serviceable moving parts per OEM guidelines. This includes: all friction discs, all bearings, pressure and suction filters, and the pump.

Subsystem assembly and testing before installation where possible.

Final assembly strictly to OEM manuals, observing all tolerances and torque specs.

Test-bench run measuring all required oil pressures, speed and temperature sensors via our dedicated software, with results recorded for future use.

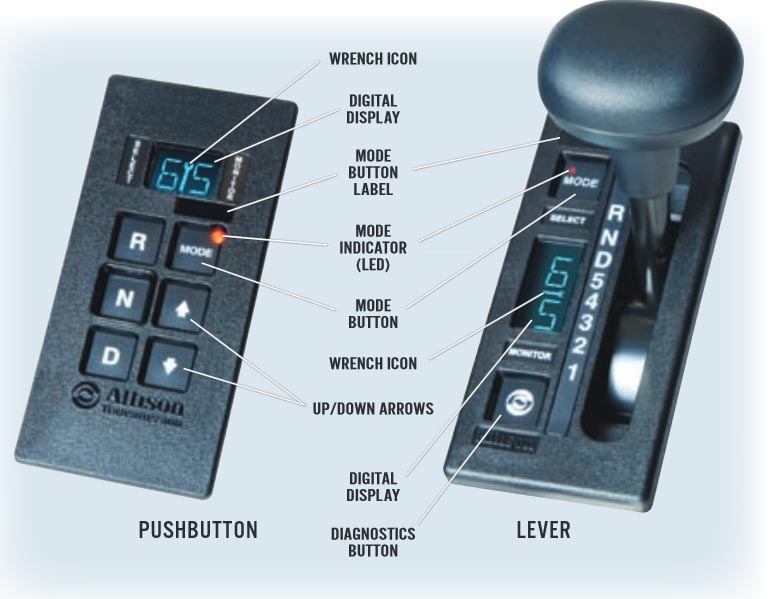

In partnership with specialized local firms and leading global providers, we repair transmission ECUs (electronic control units) and shifters—whether joystick or pushbutton—for the brands we support. If your ECU or shifter is beyond repair, we can supply a pre-programmed unit from abroad at very competitive prices.

The transmission, torque converter, pump and associated hydraulics are critical in transferring power from engine to wheels. Each unit’s operation depends on the others; therefore, whenever any unit is repaired or rebuilt, the balance of the whole driveline must be checked before considering the repair complete.

When installing a new or rebuilt transmission, the oil cooler and related lines must be thoroughly cleaned. Methods may vary, but at a minimum you should:

Completely drain the system.

Undo and clean all lines. If possible, remove them from the machine.

Replace all filters and clean the filter bases.

Clean the cooler thoroughly. It must be flushed with oil and compressed air opposite to the normal flow until all debris are removed. Flushing in the normal direction will not clean it adequately. Remove and refurbish the cooler if necessary. In all cases verify cleanliness and cooling circuit effectiveness.

Reinstall removed components and use only the correct lubricant. Fill the transmission to the FULL mark (or until oil runs from the FULL check port). Refit dipstick/plug. Start and idle for 1–2 minutes to fill circuits. Recheck level at idle and top up to LOW. Recheck hot (82.2–93.3 °C) and top up to FULL.

Reinspect all lines for leaks and tighten where necessary.

Remember to change filters after 50 and 250 operating hours and then every 500 hours unless otherwise specified.

Every 1000 hours drain with oil at 65.6–93.3 °C, clean the inlet screen, and refill per these instructions.

Standard oil/filter intervals assume average loads and climate. Under extreme conditions, adjust intervals accordingly.

Use only approved lubricants and GENUINE filters/parts; otherwise no warranty of any kind applies.